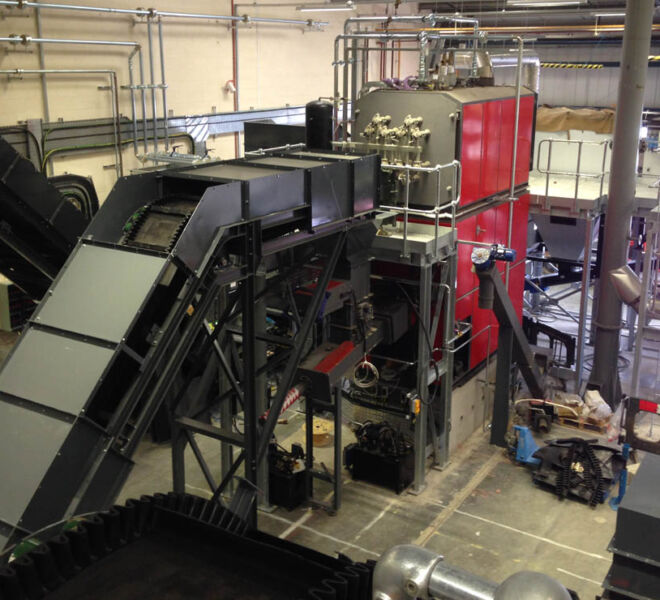

An outstanding record of fabricating and constructing steel silos for both raw materials and liquid storage

Wright Engineering manufacture robust, high-performance silos to suit all types and quantities of material and can design and manufacture to the specific requirements of your process. We have designed, fabricated and constructed silos for all the major industries and our experience in the bulk storage market places us as the leading fabricator in this field. Many silos are often designed to fit within confined areas of operating sites, in these cases, jacking construction techniques can be utilised to allow for safe construction at low level.

In most cases, silos form part of a larger scope whereby feed and discharge means are supplied by Wright Engineering also. Our materials handling expertise enables us to accurately specifiy and design both elements ensuring client and product requirements are met on all counts.

Standard & Bespoke Solutions

We can develop silos to store everything from foodstuffs and volatile chemicals to fine powders, fibrous materials or cohesive products. In addition, we offer a range of standard silo sizes in carbon steel and stainless steel. Our state-of-the-art manufacturing facilities enable us to fabricate complete, ready-to-install storage vessels up to 5 metres in diameter. Tanks, hoppers an vessels also fall within our field of expertise having designed many to suit bespoke applications. Accompanying silo accessories and safety systems are available for supply also enabling the delivery or ‘turnkey’ silos.

Our Silo range includes a multitude of options and specifications, which includes, but is not limited to…

- Heat transfer jacket according to the thermal duty and media available

- Options for electric trace heating for temperature maintenance applications

- Vertical or horizontal agitation

- Cone bottom skirt supported design (often used in sugar applications)

- Venting filters and explosion venting

- Fluidised discharging arrangements

- Dehumidification

- Weight management via load cell mounting

![]()

For more information and enquiries on any of our products listed, please contact Wright Engineering directly. A member of staff is on hand to discuss and answer any questions you may have…

Wright Engineering U.K. Head Office & Works:

Carlton Forest, Red Lane, Blyth Road, Worksop, Nottinghamshire, S81 8BP, United Kingdom

Services

An unrivalled reputation for the design, manufacture, installation & commissioning of innovative engineering solutions…

Sectors

Our continued success has seen expansion into sectors that play to the strengths of our highly experienced team…

Showcasing the many projects we deliver satisfying time, budget and functional requirements that would otherwise go unseen by anyone other than end users. Please explore our extensive portfolio…